Ex Proof Wire Rope Hoist Technology

The largely maintenance-free components of the modular wire rope hoist are optimally matched to each other. They guarantee constant performance, high efficiency and long service life. The standard safety components such as gear limit switch, motor temperature control and overload device, or even an optional additional brake, increase workplace safety.

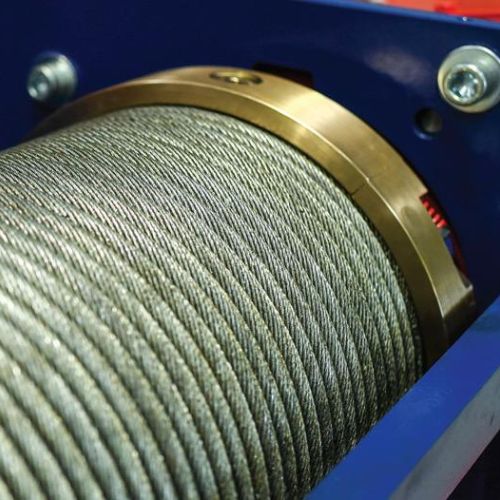

With many hazardous area cranes destined for harsh environments, the ES hoist’s modular construction lends itself to interchanging various parts as options to suit. Options include a grade 316 stainless steel pressure roller mechanism, guards, parts and fasteners for offshore/marine applications. Non-sparking features available are solid bronze wheels and guide rollers. Unique to the ES hoist is a bronze rope guide. Surface treatment options include full hot dip galvanizing hoist skeleton, followed by 240µm epoxy paint system. Where a hoist frame is required to be galvanized to preserve machining accuracy, the frame is pre-machined, and finish machined after treatment.