FEM Selection

The following table indicates the theoretical service life D in hours for FEM groups 1 Bm, 1 Am, 2 m, 3 m and 4m.

| Drive group | 1Bm/M3 | 1Am/M4 | 2m/M5 | 3m/M6 | 4m/M7 | |

| Line | Load population | Theoretical service life D (h) | ||||

| 1 | light | 3 200 | 6 300 | 12 500 | 25 000 | 50 000 |

| 2 | medium | 1 600 | 3 200 | 6 300 | 12 500 | 25 000 |

| 3 | heavy duty | 800 | 1 600 | 3 200 | 6 300 | 12 500 |

| 4 | very heavy duty | 400 | 800 | 1 600 | 3 200 | 6 300 |

In addition to the mean working time per day, tm (total average hours of operation of the hoist per day), the correct assessment of the load population is essential for selecting the appropriate drive group. The value tm is given by the following equation:

| tm | = | 2 x mean lifting hight (m) x load cycles (1/h) x working time (h/day) |

| 60 (min/h) x lifting speed (m/min) |

Mean lifting height

The average hook travel under actual operating conditions

Load Cycles

The average number of lifting operations per hour. A load cycle consists of one lifting and one lowering operation, i.e. two hook movements (lifting operations with an empty hook as a result of process conditions must also be taken into account in determining load cycles, but also make the load population determined less severe.

Working Time

Average working time per day within which the average load cycles per hour are performed.

Lifting Speed

Average lifting speed (normally the maximum lifting speed) at which the load cycles are performed.

The selection of the next highest FEM group results in a doubling of the theoretical service life if the operating conditions assumed remain unchanged.

Further information on this rather complex subject is given by FEM 9.755 and the fourth supplement to accident prevention regulation VBG 8 for winches, hoists and traction systems. We will also be pleased to send you our planning service form for selecting the correct FEM group as well as an article concerning the determination of remaining service life.

If the mean working time tm and the load population are known, the correct drive group in accordance with DIN 15020 or FEM 9.755 can be selected using the following table.

| Load population | Definition of load population | Mean working time tm per working day in h | ||||

|

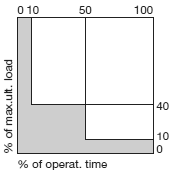

1 (Light) |

(k ≤ 0.50) Only operated at maximum load in exceptional cases, mainly operated at very low load, small dead load  |

≤2 | 2 – 4 | 4 – 8 | 8 – 16 | > 16 |

|

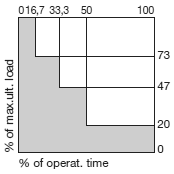

2 (Medium) |

(0.50 < k ≤ 0.63) operated quite frequently at maximum load, operated continuously at low load, medium dead load  |

≤ 1 | 1 – 2 | 2 – 4 | 4 – 8 | 8 – 16 |

|

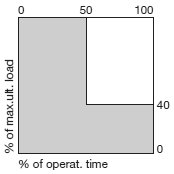

3 (Heavy Duty) |

(0.63 < k ≤ 0.80) operated frequently at maximum load, operated continuously at medium load, heavy dead load  |

≤ 0.5 | 0.5 – 1 | 1 – 2 | 2 – 4 | 4 – 8 |

|

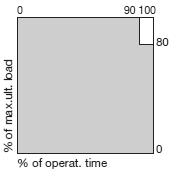

4 (Very Heavy Duty) |

(0.80 < k ≤ 1) operated regularly at maximum load, very heavy dead load  |

≤ 0.25 | 0.25 – 0.5 | 0.5 – 1 | 1 – 2 | 2 – 4 |

| Drive/FEM group in accordance with DIN 15020 or FEM 9.511 | 1Bm | 1Am | 2m | 3m | 4m | |